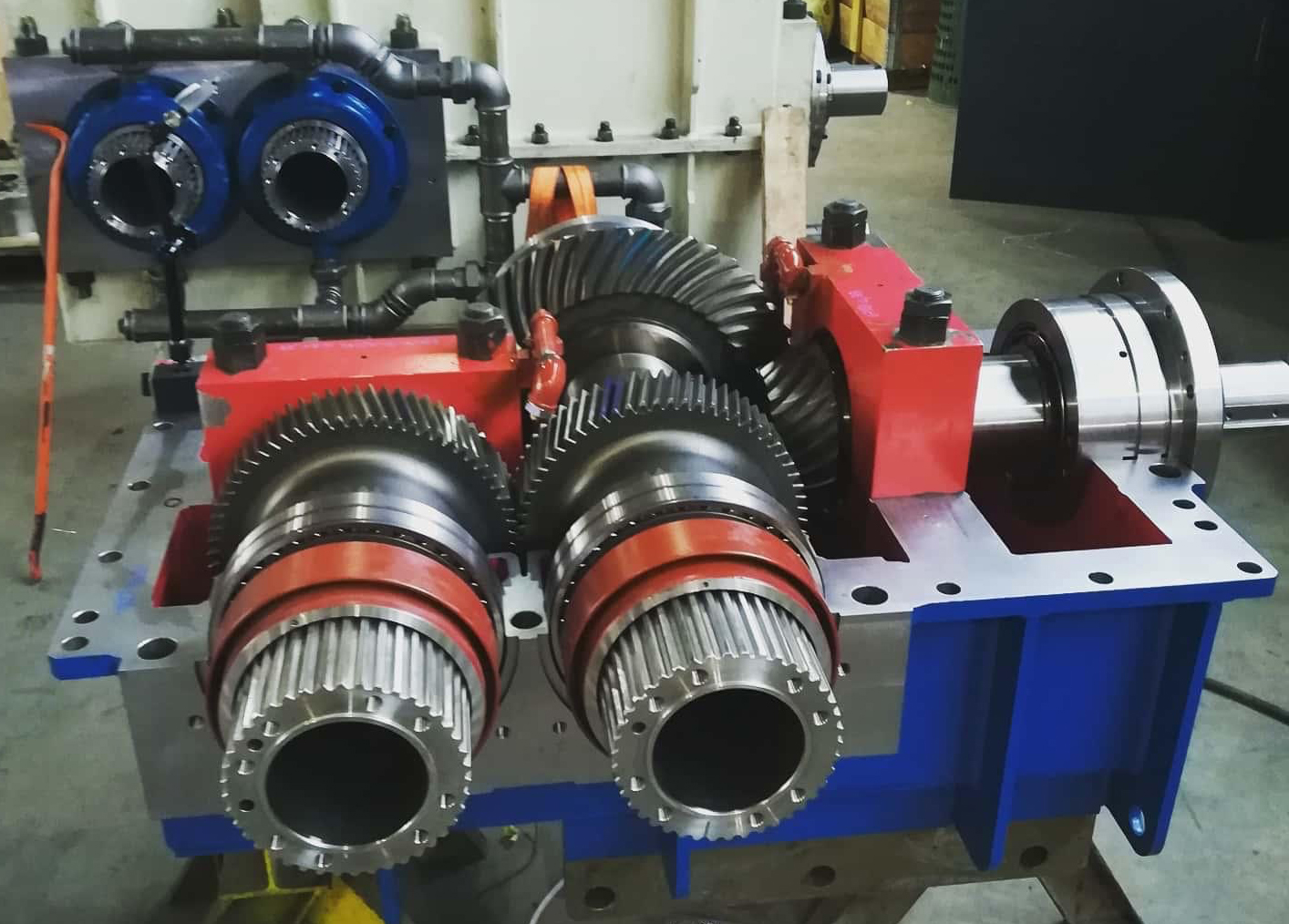

Turnkey mechanical and precision machining

A choice that translates into multiple advantages for the customer, who receives a turnkey finished product with a single order, saving time and reducing the complexity of the process.

The final quality of the product is guaranteed by scrupulous checks carried out on the entire production process which is carried out entirely at the company itself.

Thanks to these characteristics, Averoldi S.r.l. is able to offer complex machining quickly and with a high quality level.

The future of Averoldi S.r.l.: quality is the goal

As far as turning, boring, milling and carpentry are concerned, Averoldi S.r.l. is able to handle a very wide range of products, ranging from a few ounces in weight to over 60 tons. A flexibility that allows us to respond to the most diverse needs of customers.

Starting from 2024, important investments are planned to improve the quality of the processes and of the finished product, such as new cutting-edge machinery and the construction of the metrological room, which will allow the testing of even small-sized pieces.

"Constantly improving products and processes - without compromise - is the main objective that guides the evolution of our company towards a future in which quality is increasingly the protagonist".

(Luca Averoldi, CEO Averoldi Srl)

Averoldi S.r.l.: mechanics with a green soul

For some time, in fact, the company has been using (unless otherwise explicitly requested by the Customer) water-based paints, which do not contain solvents and are therefore much less impactful on the environment and on the health of the personnel.

In the coming months, work will be completed on the construction of a large corporate photovoltaic plant, with a capacity of no less than 50 kWp, which will allow Averoldi S.r.l. to use a renewable and non-polluting source for its energy supply.